Forestry

There's more to this profession than just growing, then

harvesting trees for money. Owning and managing

forests is a job with special benefits.

People buy, or continue owning wooded land for

differing, and personal reasons. The old term,

my forest is under multiple-use management says it. Along with the

growing trees, those acres also bring wildlife, relaxation,

exercise and natural beauty for all to see. And public

good too, as watersheds and more.

People buy, or continue owning wooded land for

differing, and personal reasons. The old term,

my forest is under multiple-use management says it. Along with the

growing trees, those acres also bring wildlife, relaxation,

exercise and natural beauty for all to see. And public

good too, as watersheds and more. The business aspects do matter, because owning carries along expenses of ownership, like insurance and taxes. Access roads and and boundary lines need to be maintained. Forest management, in the financial sense - sustainably lets the growing forest pay for its own upkeep, with some profit besides. Money can come in, for example, from timber sales, hunting access fees, special crops like Christmas trees, short term recreational leases and subsurface mineral leases which do not allow surface disturbance.

Tree cutting is the tool for improving and protecting forests

Thinning or

salvage is planned logging that removes smaller or poor

quality trees, eliminating those with insect or disease

pests and improving growth conditions in the residual

stand.

Thinning or

salvage is planned logging that removes smaller or poor

quality trees, eliminating those with insect or disease

pests and improving growth conditions in the residual

stand. The owner's choices matter here; small game hunters frequently keep species of trees and shrubs that offer shelter and food for wildlife.

Logging crews need companies to buy low-grade logs, poletimber and chips they produce.

The forestry activity is often called a low-grade sale; generating mostly low value commodity, or bulk sale, products. The improvement in forest condition is the benefit most owners expect. Most also want some cash payment, but frequently logging costs, together with freight expense to distant buyers leaves little or no cash income for to the landowner.

Low-grade sales can generate more revenue with higher value AND local markets

There is meaning behind the double emphasis. Freight distance is key to the owner's value of standing trees. Whether the product shipped is poletimber or chips, trucking costs vary little over the first 20 miles, but for longer distances the expense goes up with mileage.

The most reliable buyers of wood chips or roundwood traditionally have been large plants that depend on logging crews working up to 150 miles away. As an estimate, at that distance the per-load revenue will drop by $300 or more, about $12-14 for each delivered ton of the product. Mill wood buyers may apply zone-pricing to make up the difference for the wood producer when the mill needs to increase the number of deliveries, but under normal times they prefer to "stay in closer" to save money. Logging crews go out of business when they cannot sell some wood profitably every week.

A local demand for low-use wood exists today, without a business to serve it.

The heat supply market has

not interested American foresters and wood producers so far,

but opportunities await the timber industry as more  people

ask for heat and cooling from renewable energy

sources.

Wood-to-heat facilities like the college campus boiler plant

(right) use less wood per hour than big mills, but they can

afford to pay similar prices for wood chips of the same

acceptable quality as the mill, but they can be much closer

to the job.

people

ask for heat and cooling from renewable energy

sources.

Wood-to-heat facilities like the college campus boiler plant

(right) use less wood per hour than big mills, but they can

afford to pay similar prices for wood chips of the same

acceptable quality as the mill, but they can be much closer

to the job.

Selling

(pick a number, say 2) loads per week, every week to the

local outlet, means each crew has another dependable

source of income to cover logging equipment, manpower and

profit, while also paying reasonable return to the forest owner on his tree-farm

investments. Today, wherever you are in America, the

potential to develop new, well designed heat-from-wood chip

facilities is almost limitless.

The missing factor has been

people and the business in the middle. Wood producers,

forest owners or managers with the low-grade timber, who

know timber production AND make an effort learn the fairly

simple business of heat energy supply contracting.

Better still, they partner with neighbors in their community

for the purpose.

Where is the money coming from?

Well managed businesses can provide complete,

quality service at a profit based on the difference

between value of wood chips in the truck,

and the corresponding value of the heat

generated from it.

Well managed businesses can provide complete,

quality service at a profit based on the difference

between value of wood chips in the truck,

and the corresponding value of the heat

generated from it.

Customers want comfort, not

chips, fuel oil or any other fuel. Selling them that comfort

(heat) using a renewable energy source is the service. Value

is added to wood chips only when the new heat supply

contracting business begins operating.

Keeping occupants comfortable and supplied with service hot

water requires a the same quantity of heat energy with

either fuel type. Wood chips can do the same job for

less money. Facility operators benefit in other ways

by contracting for heat, and for that reason, they can be

willing to pay nearly the same as if they were using the

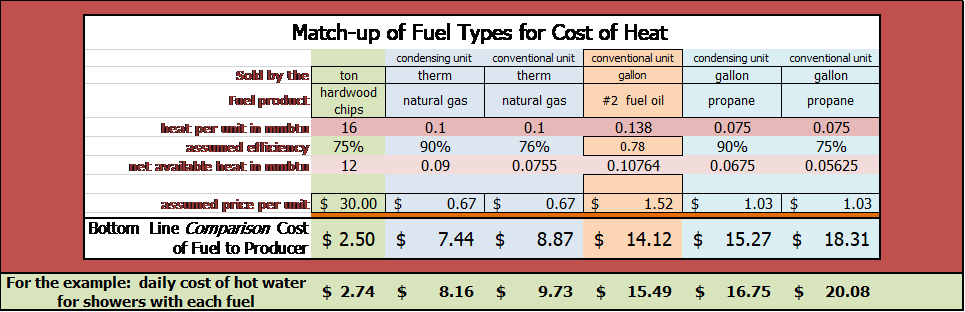

conventional source. For perspective,

consider this example with recent energy cost data for a 50

unit apartment complex in Pennsylvania. The

bottom(green) row figures are the estimated fuel energy cost

of hot water used (only) for showers by tenants over a

single 3-hour period.

So why don't managers of hotels, laundries,

apartment complexes or swimming pools do it

themselves?

A

simple but very understandable answer:

Their attention is on

satisfying customers, as is yours. Hotel staff

people are hired to help guests, not service heat

pumps or boilers.

Even today, American biomass heating equipment companies sell and install the units, then expect the new owner to learn and follow the directions and manage fuel supply, two areas they don't know, or care to learn. It does require some staff time. Wood chip or pellet heat systems take more attention than the gas, oil or electrical units that the owners already know and trust. Management will not risk complaints about heat, cooling or cold showers.

Today's biomass heating

(biothermal) equipment does work well when installed and

operated as designed. The business develops as a

service, giving customers clean renewable energy they want

and can promote, in ways that eliminate their sense of perceived

risk. Managers of hotels and other good

candidate buildings can be quite willing to contract for the

service with a qualified company when the terms are

right.

Why team with RPG?

Land owners, foresters and

wood producers need new markets for low-grade timber and

urban green woody biomass. We offer assistance in

market development across all types of timber. With

income from these new businesses, the industry can

continue using good practices to benefit the entire forest

community and still generate a profit. Our experience

includes buying and selling timber, chips and hogged fuel,

and also in building energy use, efficiency and renewable

fuel applications.

Member:

Member:

Society of American Foresters

Forest Guild

PA Council of Professional Foresters

NC Forestry Association

PA Forest Products Association

2018-Oct. 13

2018-Oct. 13